If you are a novice to the wonderous benefits of taking CBD or a long-time consumer, its important to know how the CBD oil is extracted from the hemp plant because there are major differences. I am writing about the 3 best CBD extraction methods in 2020 used by manufacturers in this post, but as technology changes, more extraction methods are a certainty.

The 3 Best Extraction Methods in 2020 Are:

- Supercritical CO2 Extraction

- Butane or Propane Extraction

- Alcohol Extraction

Supercritical CO2 Extraction

The best way to define Supercritical CO2 extraction in terms that don’t make it seem too over-complicated is to break it down into simpler steps that are easier to understand.

CO2 (carbon dioxide) is a greenhouse gas that is harmless in small quantities and is one of the most important gases on earth because plants use it to produce photosynthesis.

It also provides the carbonation or “fizz” in all soft drinks and most beers, so you have probably been a life long consumer. And being human, it’s the gas that we exhale after taking in a breath of air. We breathe in oxygen and exhale CO2

However, CO2 is a gas and in order to convert it into a liquid where it can saturate the biomass and extract all the natural botanicals and cannabinoids requires 2-things.

- Temperature

- Pressure

The temperature required to convert CO2 from a gaseous state to where it behaves as a supercritical fluid needs temperatures above 87.8° degrees and to maintain a consistent pressure level of at least 1,070 PSI in order for CO2 to remain in a liquid state.

Compare that to propane gas which we have all used at one time or another if you have ever done any barbequing on a gas grill, can maintain in a liquid state at a room temperature of 70°, and pressurized in a tank between 100 and 200 psi.

For example, a standard 20-pound propane tank at 70° will have and an internal pressure of 145 psi for the propone to remain in a liquid state.

Engineering and technology are largely responsible for breakthroughs in the modern design and manufacturing of Supercritical CO2 processing equipment that is used today.

This equipment can consistently produce the precise temperatures and pressures in order to convert CO2 into a liquid state where it can be used to extract the rich cannabinoids locked within the leaves and flowers of the hemp plant. Without the benefits of using state-of-the-art Supercritical CO2 equipment, this clean extraction process would be next to impossible to perform.

A more efficient, safer, and organic way of obtaining hemp plant extracts while preserving the plant’s natural properties and has been used since the early 90’

Held at or above its critical temperature and critical pressure…ever seen dry ice? Well it’s CO2 that has been converted to liquid form and then exposing it a temperature of -109°

Co2 extraction is without question, one of the best methods to produce high-quality hemp extracts- without using any harmful solvents

CO2 is a non-toxic solvent resulting in a total chemical purity of the final product

CO2 recycling, which significantly reduces carbon footprint and co2 storage

So far we’ve covered how CO2 is transformed from a gaseous state into a liquid state by means of Supercritical CO2 processing, lets talk about how it happens to be one of the most cost-effective and safest methods for extracting 90% the essential oils and phytochemicals from the hemp plant and producing a high purity CBD oil.

The CO2 Extraction Process:

- Biomass (comprised of hemp leaves and flowers) is milled down to the same consistency as that of tobacco for best extraction.

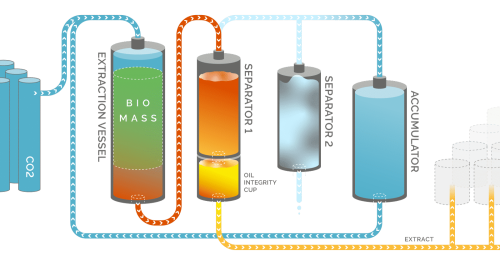

- The biomass in various quantities depending on the size of the extractor (from a few pounds up to 800 or more) is loaded into a specially designed pressurized cylinder which is part of the CO2 extractor and sealed tightly.

- A highly trained and experienced technician will enter the variables directly into the computer with respect to biomass quantity so the system can calculate the precise measurements for pressure, temperature, and time of exposure.

- Once the sequence is activated, the liquid CO2 now under pressure will thoroughly saturate the biomass and begin extracting all the botanicals, CBD’s and phytochemicals.

- As the process takes place, the extracted hemp oil is systematically deposited into a specially designed collection cylinder and is now ready for the second phase of the extraction process, called winterization.

The Supercritical CO2 extraction process removes approximately 90% of all the essential botanical properties, phytochemicals, terpenes, and hemp plant waxes.

The procedure of winterization separates out the plant waxes that were collected from the extraction process so only the pure CBD oil with its full spectrum of cannabinoids and phytochemicals remains.

Without undergoing the winterization process, the extracted oil has an almost paste-like consistency, making it too thick to consume, in addition, there are virtually little to no therapeutic values from ingesting the wax.

Winterization Process:

Once the hemp oil has been extracted from the Supercritical CO2 process it needs to be winterized in order to separate out the undesirable elements from the extracted oil-like, fats, waxes, and lipids from the other plant botanicals, otherwise the oil would be cloudy, darker and have an unpleasant taste.

The paste-like hemp oil is placed in a large glass jar and then the lab technician adds 200 proof ethanol at a 10-1 ratio (1-liter of hemp oil to 10 liters of ethanol) and mixes it thoroughly until the hemp oil is completely dissolved.

The mixtures are then sealed and placed in a freezer for up to 48 hours (hence the name winterization) when the jar is removed from the freezer, the ethanol is not frozen, so they pour out the mixture using a specially designed funnel that sits on top of a large beaker and then they add a replaceable paper filter which will capture the hemp plants fats, waxes, and lipids.

The last step in the process involves distilling out the ethanol which is made up of grain alcohol which is recaptured for the next use. After the distillation process is completed, only the pure CBD oil remains, making it ready to be manufactured into oil tinctures, edibles, topicals, and pet CBD products.

Conclusion: When shopping for a premium grade CBD product be sure to ask how their oil is extracted because companies that utilize the Supercritical CO2 method ensure you are getting the cleanest CBD extraction possible.

Supercritical CO2 extraction is safe, non-toxic, non-flammable, recyclable, and better for the environment because it doesn’t produce any pollution.

Pharm-CBD is quickly emerging as one of the premier CBD companies in the country largely in part because they grow some of the best award-winning hemp strains available, that are high in CBD potency on their own farms in Kentucky.

The mature hemp plants at Pharm CBD are then harvested, cultivated and ready for processing into CBD oil utilizing the Supercritical CO2 extraction process.

Pharm-CBD produces one of the highest quality, premium-grade CBD oils in the country and you can choose their Full-Spectrum CBD Oil Tincture (CBD + 0.3% THC) or their Broad-Spectrum CBD Oil TIncture which is (THC Free)